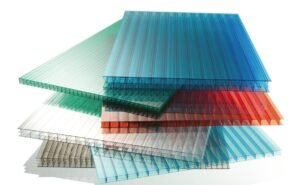

Multi-wall polycarbonate sheets are very tough and potent sheets. They are 200 times stronger and 50 times lighter than ordinary glass. They are taking over many industries and replacing traditional building materials. Some of their benefits are given below:

- Best insulators

- High thermal resistance

- Lightweight and strong

- Cost-effective and durable

- Anti UV, anti-fog and anti-scratch

- Customizable

- Log life span and manufacturer’s warranty

- Easy installation and low maintenance.

These were some of the many advantageous characteristics of multi-wall polycarbonate sheets. Now let’s talk about their types one by one.

- Twin wall polycarbonate sheets:

Twin wall polycarbonates are made by the connection of two polycarbonate walls with gaps and passages. The twin-wall polycarbonate sheets come with attention-grabbing styles and are very easy to install. Their recycling and machining are easy. They are strong and durable. They have a high tolerance level which helps in the reduction of the cost and labor. They have hot and cold bending capabilities. They have an anti-fog, anti UV and anti-scratch layer. They are flame retardant and weather resistant. They are used in greenhouses, interior and exterior of buildings, telephone booths and roofing etc.

- Three wall polycarbonate sheets:

A three-wall or a triple wall polycarbonate sheet is, as the name indicates made of three layers of polycarbonate sheets joined together. There are air trapping gaps between each layer which makes them the best insulator and soundproofing barriers. They have a great tendency for light transmission and are very lightweight. They are customizable in many shapes, designs, styles, patterns and colors at YiPlastics. They are unbreakable. They lower the cost of installation and construction. They are an ideal roofing material. They are self-extinguishing in case of fire which means there is,

- No fire droplets

- Low toxicity

They are used in the manufacturing of canopies, carports, interior and exterior of the buildings and military equipment etc.

- Four wall polycarbonate sheets:

Four-wall polycarbonate sheets are made up of four polycarbonate sheets with sectioning patterns on the inside. They are very strong and lightweight. They are an exceptional choice for architecture and designs. They are made with international standard quality. The installation and handling are very easy. They have strong functional and intelligent features. The design of four-wall polycarbonate sheets makes them energy-saving and eco-friendly. It comes with a highly sensitive UV protection layer to prevent any radiation hazard

They are used in screen walls, railway stations sports grounds, roofing, security, partitions, pond covers, facades, anti-fire cabins, street walks, decoration and smoking shelters as well.

- Five Wall Polycarbonate Sheets:

Five wall polycarbonate sheets are made up of five separate polycarbonate sheets joined together to make an individual wall. They have high light transmission capacity and a highly sensitive ultraviolet radiation blocking layer. They are 200 times sturdier the ordinary glass and approximately have half the weight of traditional glass. Their applications have been growing and spreading into many industries every passing day.

They are easily customizable into the desired sizes, shapes, forms, colors and styles. The customization is fairly quick and in real-time. They are so strong that they are practically unbreakable. They are weather-resistant. They can survive any weather condition such as extreme hot and cold weather, hailstorms, snow, heavy rains and hot sunlight.

Five-wall polycarbonate sheet comes with a special drip guard coating which avoids and stops any condensation of particles and moisture and keeps the sheets clean. They are shattering free hence ideal for fabrication. On top of that, they are splinter and crack-free too. They are used as partitions and sectioning for rooms or buildings, greenhouses, skylights, pool covers, sunrooms, carports and canopies etc.

- Honeycomb Polycarbonate Sheets:

Honeycomb polycarbonate sheets are a type of multi-wall polycarbonate sheets that are designed as the pattern of a honeycomb. The sectioning or gaps between the walls are shaped like a honeycomb. This structure provides isolating air spaces and the best thermal resistance. The transparency rate is as high as up to 70 percent.

Advantages

The honeycomb polycarbonate sheets are extremely weather resistant. They are known to have the best performance in severe weather circumstances. They can survive in extremely low as well as extremely high temperatures e.g. from -40 degrees to 120 degrees Celsius. They are ideal to use in the areas of ever-changing weather conditions.

They can withstand snowstorms, sandstorms hurricanes, and hailstones as well.

The honeycomb polycarbonate sheets are light and stronger than twin wall polycarbonate sheets. Their installation is easy and they do not require any extra machinery or care. They have an anti-UV and anti-scratch layer to make them eco-friendly and long-lasting. Just like the five-wall polycarbonate sheets, they also have an anti-condensation coating to keep the surface clean and visionary. The honeycomb polycarbonate sheets are used in greenhouses, roofing, skylights, sunrooms and in enhancing the interior and exterior of the buildings etc.

- Plug Structure Polycarbonate Sheets:

Plug structure polycarbonate sheets are made by joining the multi polycarbonate sheet walls together and the air spaces between them have a special pattern called the plug structures. They are a brilliant pick in multiwall polycarbonate sheets.

They are appropriate for a larger area application. They are aesthetically pleasing and eco-friendly. They have precise energy access. This function helps you to choose the amount of your energy consumption on your own.

They have very little heat transfer coefficient or the K-value. They are capable of surviving in any condition of weather. They have a flatter drape wall area and a flawless concealed frame effect. It saves energy, labor and construction costs. It lessens the overall budget compared to the traditional building materials. We at YiPlastics are offering the best sizes, 1570 mm and extra-wide 40 mm thick plug structure polycarbonate panels, which are 3 x greater than the common polycarbonate panels. We guarantee you a quick job. They are used in every official, industrial and architectural building, drape walls, interior and exterior finishes, stage plans, road signs, doors, windows, greenhouses, roofing, stadiums, skylights, warehouses and showcases etc.

If you want to choose the best multiwall polycarbonate sheets, book an appointment now.

#Multi-wall sheets

#Polycarbonates

#Twin wall

#Polycarbonate sheets